How to Choose the Right Cold Storage Manufacturer

Selecting the right cold storage manufacturer for your requirements is a must to keep perishable goods safe and operations running.

This article is your guide to assessing your requirements, evaluating a provider's experience, technology and tools, location and pricing, and ensuring they meet compliance standards and ongoing support.

With India's cold chain market set to reach INR 6,061.7 billion by 2033, working with solid cold storage manufacturers like cold storage manufacturers in Gujarat creates efficient cold storage facilities while controlling cold storage project costs.

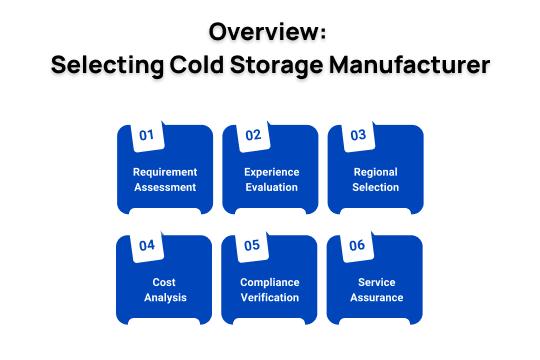

Overview: Selecting Cold Storage Manufacturer

- Requirement Assessment: Match manufacturer skills with storage volume/product types for smooth cold storage projects.

- Experience Evaluation: Focus on target companies with more than 20 years and 2,500+ projects under their belts.

- Regional Selection: Cold storage manufacturer in Gujarat for faster installs and fewer logistics hassles.

- Cost Analysis: The cold storage projects can be cut by up to 30% in modular builds.

- Compliance Verification: Check ISO, HACCP & FSSAI certifications for food or pharma safety twice.

- Service Assurance: Pick firms that have great after-sales service to run your cold storage without any hassle.

Define Your Cold Chain Requirements

All good cold storage setups start with knowing what you need. Fruit exporters may need a banana ripening chamber, and pharmaceutical outfits require a temperature range of +2°C to +8°C for tight control of vaccines.

Make sure this step fits your cold storage facility so you avoid expensive fixes later, which increase cold storage project costs.

- Document Capacity Needs: Most dairy setups need 500 MT spaces. Check accordingly for sizing current & future volumes.

- Identify Key Features: Search cyclopentane PUF panels for higher energy efficiency and lower operation costs for your cold storage project.

- Consider Regional Fit: A local cold storage manufacturer creates solutions for handling area-specific goods like fresh produce or frozen items.

Evaluate Manufacturer Experience and Reputation

A track record of satisfied customers tells you a cold storage manufacturer can perform under pressure. Look for manufacturers with 15+ years of experience and firms that have survived supply chain disruptions over the years.

Having a portfolio with thousands of clients shows dependability and reduces risks to little or nothing when implementing your cold storage facility and project.

- Examine Project History: Request examples of 2,000 MT cold storage facilities for cooperatives.

- Review Testimonials: Ice cream producers or seafood handlers share insight on everyday reliability and performance.

- Inspect Active Installations: Touring operational cold storage facilities lets you verify panel quality and system smoothness in person.

- Highlight Sector Successes: Choose those that meet your industry standards, such as blast freezing for frozen goods.

Assess Technological Capabilities and Innovation

Forward-thinking technology sets a cold storage manufacturer apart from the crowd. Remote monitoring through app-connected sensors monitors temperatures across sites, and efficient motors reduce power use amid rising demands.

As cold storage warehousinghits USD 59 billion by 2030, these tools add long-term value to your cold storage facility.

- Review Material Quality: High-density PUF panels with fire-resistant Class O ratings withstand tough conditions reliably.

- Explore Specialized Tools: Features like CO2 scrubbers assure uniform ripening of fruits for cold storage projects.

- Request Live Tests: Simulate running a -20°C chamber to confirm steady performance.

- Embrace Modular Options: These designs allow quick adjustments and make your cold storage facility flexible to changing requirements.

Analyze Costs and Long-Term Value

Standard facilities range between INR 1,500 and 3,000 per MT, whereas advanced pharmaceutical-grade units cost INR 5,000/MT.

Generally, panels account for 40%, refrigeration 30%, and installation around 20% of the costs. The investment in higher efficiency systems usually has a payback in 3-5 years, and the quality solution beats the low cost bids with high operating expenses.

- Factor in Hidden Costs: Comprehensive proposals should cover commissioning, upgrades & maintenance to avoid unexpected charges.

- Secure Robust Warranties: For longer reliability, negotiate a 10-year warranty on panels.

- Use Cost Analysis Tools: Comparative cost breakdowns enable realistic ROI forecasting & financial planning.

Verify Compliance and Sustainability Measures

There are industry standards that every cold storage facility must follow for safety, legality and efficiency.

Reputable cold storage manufacturers include leak detection systems, fire-safe components and eco-friendly technologies which are also eligible for sustainability incentives.

- Audit Certifications: Before finalizing partnerships review all ISO, HACCP, and FSSAI documents and look for discrepancies or expired approvals.

- Focus on Eco-Friendly Builds: Low energy designs lighten your cold storage project footprint.

- Incorporate Reliability Boosts: Backup power protects against outage protection in remote setups.

- Pursue Verified Credentials: These get funding & build trust in sustainable cold storage facilities.

Examine After-Sales Service Framework

The real value of a investing in modular cold room and cold storage investment is only realised after installation: reliable after-sales support determines long-term performance.

The right manufacturer will give you 24/7 assistance, routine maintenance and fast access to spare parts to minimise downtime and keep you running.

A wide range of training programs equips your team to perform daily functions and handle minor problems before they become serious issues.

- Verify Response Times: Establish emergency response procedures upfront, with a 4-hour response time being about the industry standard.

- Evaluate Maintenance Plans: Preventive maintenance visits and stocking of key spare parts save you money on breakdowns.

- Prioritise Staff Training: Trained operators can manage systems independently and maintain peak performance.

- Learn from Past Performance: Facilities with service delays suffered substantial losses. Select manufacturers who can service your investment quickly and reliably.

Partnering with Blue Ice India for Excellence

This guide documents the steps to choose a cold storage manufacturer, from needs assessment to ongoing support for surviving India's growing cold chain.

Smart planning builds durable cold storage facilities, controls cold storage project costs, and delivers strong returns with reliable tech and standards.

Blue Ice India has been a cold storage manufacturer for over a decade. We have delivered customised cold storage solutions for more than 2,500 clients, from large 2,000 MT facilities to specialist chambers.

Our ISO-certified experts ensure that every project meets your operational goals precisely and reliably. Request an estimate for your cold storage in Gujarat project. Become part of a resilient cold chain today.

Comments

Post a Comment